Part 2. Technology: aluminium extrusion + kev sib txhuam do vuam raws li lub ntsiab, laser vuam thiab FDS los yog ua rau yav tom ntej kev taw qhia

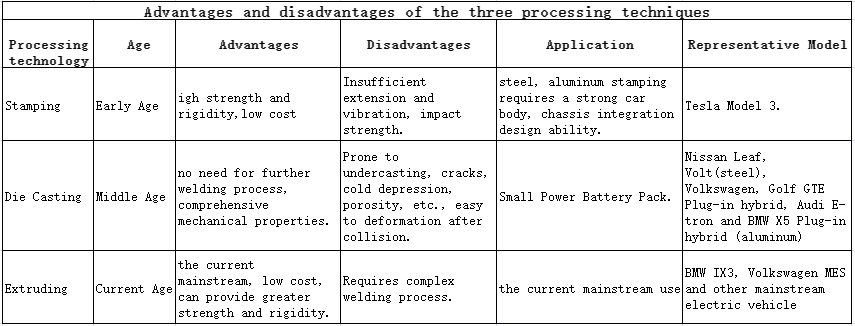

1. Piv nrog tuag casting thiab stamping, aluminium extrusion forming profiles thiab ces vuam yog lub ntsiab technology ntawm roj teeb thawv tam sim no.

1) Qhov tob ntawm lub plhaub nyob rau hauv lub roj teeb pob welded los ntawm stamping aluminium phaj, tsis txaus vibration thiab cuam tshuam lub zog ntawm lub roj teeb pob, thiab lwm yam teeb meem xav kom lub tsheb tuam txhab uas muag muaj zog integrated tsim muaj peev xwm ntawm lub cev thiab chassis;

2) Lub casting txhuas roj teeb tais hauv kev tuag casting hom txais tag nrho ib zaug molding.Qhov tsis zoo yog tias cov aluminium alloy yog qhov yooj yim rau undercasting, tawg, kev sib cais txias, kev nyuaj siab, porosity thiab lwm yam tsis xws luag hauv cov txheej txheem casting.Cov khoom sib khi ntawm cov khoom tom qab casting yog qhov tsis zoo, thiab qhov elongation ntawm cov cam khwb cia aluminium alloy yog tsawg, uas yog nquag deformation tom qab kev sib tsoo;

3) Extruded aluminium alloy roj teeb tais yog lub ntsiab lus tseem ceeb ntawm cov roj teeb tam sim no, los ntawm kev sib txuas thiab kev ua cov profiles kom tau raws li cov kev xav tau sib txawv, muaj qhov zoo ntawm cov qauv tsim, yooj yim ua, hloov kho thiab lwm yam;Kev ua tau zoo Extruded aluminium alloy roj teeb tais muaj siab rigidity, kev co kuj, extrusion thiab cuam tshuam kev ua haujlwm.

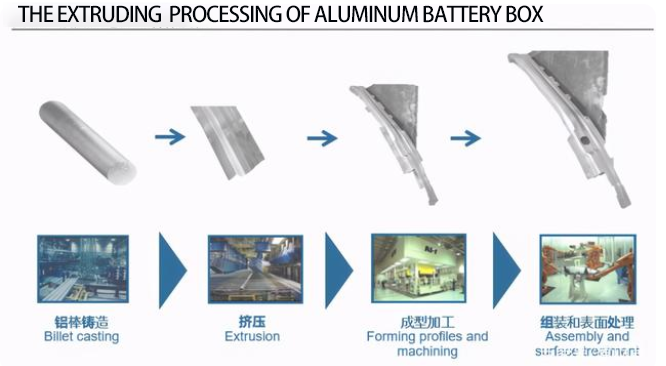

2. Tshwj xeeb, cov txheej txheem ntawm txhuas extrusion los tsim lub thawv roj teeb yog raws li hauv qab no:

Lub phaj hauv qab ntawm lub thawv lub cev yog tsim los ntawm kev sib txhuam do vuam tom qab lub txhuas bar yog extruded, thiab hauv qab lub thawv lub cev yog tsim los ntawm vuam nrog plaub sab phaj.Tam sim no, lub ntsiab aluminium profile siv zoo tib yam 6063 lossis 6016, lub zog tensile yog qhov nruab nrab ntawm 220 ~ 240MPa, yog tias siv lub zog siab dua extruded aluminium, tensile lub zog tuaj yeem ncav cuag ntau dua 400MPa, piv nrog lub thawv zoo tib yam aluminium profile tuaj yeem txo qhov hnyav ntawm 20% ~ 30%.

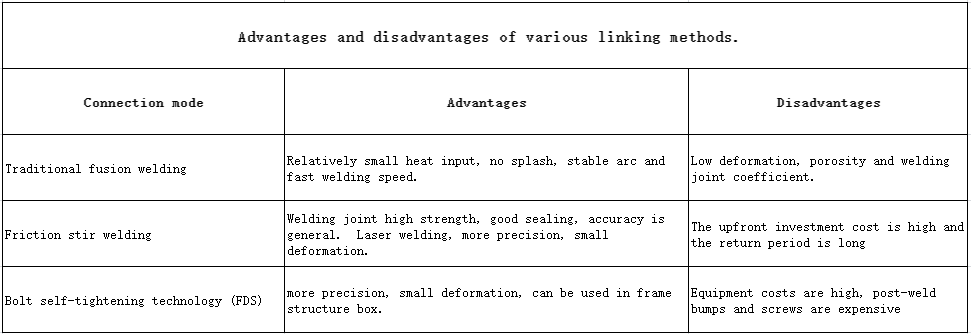

Vim yog qhov yuav tsum tau splice qhov profile, vuam tshuab muaj kev cuam tshuam zoo rau lub tiaj tus thiab qhov tseeb ntawm lub thawv roj teeb.Roj teeb lub thawv vuam tshuab tau muab faib ua cov vuam tsoos (TIG welding, CMT), thiab tam sim no lub ntsiab kev sib txhuam vuam (FSW), ntau tshaj laser vuam, ntsia liaj qhov rooj nws tus kheej-tightening technology (FDS) thiab kev sib txuas tshuab.

TIG welding yog nyob rau hauv kev tiv thaiv ntawm inert roj, siv lub arc generated ntawm tungsten electrode thiab weldment rau tshav kub yaj puag hlau thiab sau hlau, thiaj li mus tsim zoo welds.Txawm li cas los xij, nrog rau kev hloov pauv ntawm lub thawv qauv, lub thawv loj loj tuaj, cov qauv profile ua nyias dua, thiab qhov tseeb qhov tseeb tom qab vuam tau zoo dua, TIG vuam yog qhov tsis zoo.

CMT yog MIG / MAG welding txheej txheem tshiab, siv cov mem tes loj tam sim no los ua kom cov vuam hlau arc smoothly, los ntawm cov khoom nto nro, lub ntiajteb txawj nqus thiab cov neeg kho tshuab twj, tsim ib qho txuas txuas ntxiv, nrog cov cua sov me me, tsis muaj txaws, arc stability thiab ceev vuam ceev thiab lwm yam zoo, tuaj yeem siv rau ntau yam khoom siv vuam.Piv txwv li, lub thawv qauv hauv qab pob roj teeb siv los ntawm BYD thiab BAIC qauv feem ntau siv CMT vuam tshuab.

4. Traditional fusion welding muaj teeb meem xws li deformation, porosity thiab qis vuam sib txuas coefficient tshwm sim los ntawm cov cua kub loj.Yog li ntawd, ntau npaum thiab ntsuab kev sib txhuam do vuam tshuab nrog ntau dua vuam zoo tau lug siv.

FSW yog ua raws li cov cua sov uas tsim los ntawm kev sib txhuam ntawm cov rotating sib tov koob thiab lub xub pwg nyom thiab lub hauv paus hlau raws li lub tshav kub qhov chaw, los ntawm kev sib hloov ntawm rab koob sib tov thiab lub axial quab yuam ntawm lub xub pwg nyom mus cuag lub plasticization ntws ntawm lub lub hauv paus hlau kom tau txais kev sib koom ua ke.FSW vuam sib koom ua ke nrog lub zog siab thiab kev ua haujlwm zoo sealing yog dav siv hauv kev lag luam roj teeb lub thawv vuam.Piv txwv li, lub thawv roj teeb ntawm ntau tus qauv ntawm Geely thiab Xiaopeng tau txais kev sib txhuam ntawm ob sab dov vuam qauv.

Laser vuam siv lub laser beam nrog lub zog ceev kom irradiate saum npoo ntawm cov khoom yuav tsum tau welded rau yaj cov khoom thiab tsim ib tug txhim khu kev qha kev sib koom tes.Cov khoom siv laser vuam tsis tau siv dav vim yog tus nqi siab ntawm kev nqis peev thawj zaug, lub sijhawm rov qab mus ntev, thiab qhov nyuaj ntawm aluminium alloy laser vuam.

5. Txhawm rau txo qhov cuam tshuam ntawm vuam deformation ntawm lub thawv loj qhov tseeb, bolt self-tightening thev naus laus zis (FDS) thiab kev sib txuas tshuab tau qhia, ntawm cov tuam txhab paub zoo yog WEBER hauv Tebchaws Yelemees thiab 3M hauv Tebchaws Meskas.

FDS kev twb kev txuas tshuab yog ib yam ntawm cov txheej txheem txias ntawm tus kheej-tapping ntsia hlau thiab ntsia liaj qhov rooj kev twb kev txuas los ntawm zawm ncej ntawm cov khoom siv chaw ua hauj lwm kev kub ceev kev sib hloov ntawm lub cev muaj zog yuav tsum tau kev cob cog rua rau lub phaj kev sib txhuam kub thiab yas deformation.Nws feem ntau yog siv nrog cov neeg hlau thiab muaj qib siab ntawm automation.

Nyob rau hauv lub tshav pob ntawm lub zog tshiab lub roj teeb pob raug tsim, cov txheej txheem yog tsuas yog siv rau lub thav duab qauv lub thawv, nrog rau cov txheej txheem kev sib txuas, thiaj li yuav ua kom muaj kev sib txuas muaj zog txaus thaum paub txog kev sib khi ntawm lub thawv.Piv txwv li, lub roj teeb rooj plaub ntawm lub tsheb qauv ntawm NIO siv FDS thev naus laus zis thiab tau tsim ntau ntau.Txawm hais tias FDS thev naus laus zis muaj qhov zoo tshaj plaws, nws kuj muaj qhov tsis zoo: cov cuab yeej siv siab, tus nqi siab tom qab vuam protrusions thiab screws, thiab lwm yam, thiab cov kev ua haujlwm kuj txwv nws daim ntawv thov.

Ntu 3. Kev Tshaj Tawm Kev Lag Luam: roj teeb lub thawv lag luam qhov chaw loj, nrog kev loj hlob sai

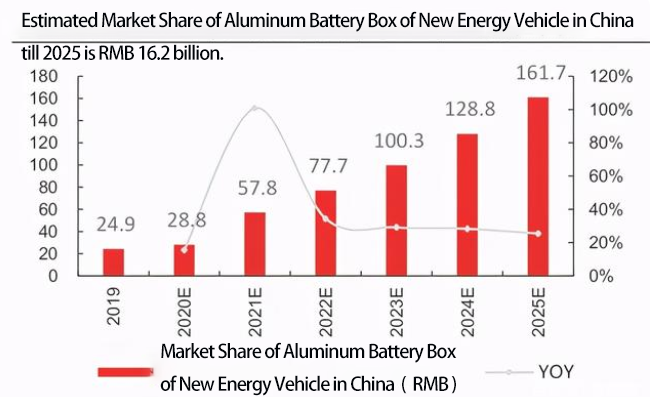

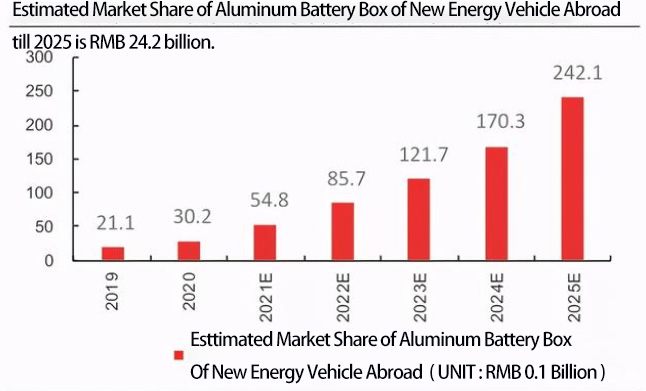

Cov tsheb hluav taws xob ntshiab tseem nce ntxiv hauv ntim, thiab qhov chaw ua lag luam ntawm lub thawv roj teeb rau lub zog tshiab tau nthuav dav sai.Raws li kev kwv yees kev muag khoom hauv tsev thiab thoob ntiaj teb ntawm lub zog tshiab, peb suav cov chaw lag luam hauv tsev ntawm lub zog tshiab lub tsheb roj teeb lub thawv los ntawm kev kwv yees qhov nruab nrab ntawm ib chav tsev nqi ntawm lub zog tshiab lub thawv roj teeb:

Cov ntsiab lus tseem ceeb:

1) Kev muag khoom ntawm lub zog tshiab tsheb hauv Suav teb xyoo 2020 yog 1.25 lab.Raws li Txoj Haujlwm Nruab Nrab thiab Lub Sijhawm Ntev ntawm Kev Txhim Kho Tsheb ntawm Kev Lag Luam Kev Lag Luam tau muab los ntawm peb Lub Chaw Haujlwm thiab cov thawj coj, nws yog qhov tsim nyog xav tias qhov muag ntim ntawm lub zog tshiab neeg caij tsheb hauv Suav teb xyoo 2025 yuav ncav cuag 6.34 lab, thiab kev tsim tawm txawv teb chaws tshiab. lub zog tsheb yuav ncav cuag 8.07 lab.

2) Kev muag khoom hauv tsev ntawm cov tsheb hluav taws xob ntshiab suav txog 77% hauv 2020, piv txwv tias qhov muag ntim yuav suav txog 85% hauv 2025.

3) Lub permeability ntawm txhuas alloy roj teeb lub thawv thiab bracket yog tswj ntawm 100%, thiab tus nqi ntawm ib lub tsheb kauj vab yog RMB3000.

Kev suav cov txiaj ntsig: nws tau kwv yees tias los ntawm 2025, qhov chaw lag luam ntawm lub thawv roj teeb rau lub zog tshiab neeg caij tsheb hauv Suav teb thiab txawv teb chaws yuav yog kwv yees li RMB 16.2 billion thiab RMB 24.2 billion, thiab qhov sib xyaw ua ke ntawm 2020 txog 2025 yuav yog 41.2% thiab 51.7%

Post lub sij hawm: May-16-2022