Ruiqifeng Factory Overview-Process Flow of Aluminium Products

1. Melting & Casting Rhiav

Peb tus kheej melting thiab casting rhiav tuaj yeem paub cov khoom pov tseg thiab rov siv dua, tswj cov nqi tsim khoom, thiab txhim kho kev tsim khoom.

2. Pwm Tsim Center

Peb cov kws tsim qauv tsim tau npaj los tsim cov nqi tsim nyog tshaj plaws thiab zoo tshaj plaws tsim rau koj cov khoom, siv peb cov kev cai ua tuag.

3. Extruding Center

Peb cov khoom siv extrusion muaj xws li 600, 800T, 1000T, 1350T, 1500T, 2600T, thiab 5000T extrusion qauv ntawm txawv tonnages, nruab nrog American-ua Granco Clark (Granco Clark) tsheb laij teb, uas tuaj yeem tsim lub voj voog loj tshaj plaws mus txog 50 hli ntau yam.

5000 Tuj Extruder

Extruding Rhiav

Extruding Profile

4. Kev laus rauv

Lub hom phiaj tseem ceeb ntawm lub qhov cub hluav taws xob laus yog tshem tawm kev ntxhov siab los ntawm kev kho cov laus ntawm aluminium alloy thiab stainless hlau stamping qhov chaw. Nws kuj tseem siv tau rau ziab cov khoom siv tib yam.

5. Powder Txheej Rhiav

Ruiqifeng muaj ob kab kab rov tav hmoov txheej thiab ob ntsug hmoov txheej kab uas siv Japanese Ransburg fluorocarbon PVDF txau cov cuab yeej thiab Swiss (Gema) cov khoom siv tshuaj txau.

Powder Coating Workshop Overview

Kab rov tav hmoov txheej kab

Vertical hmoov txheej kab-1

Vertical hmoov txheej kab-2

6. Anodizing Rhiav

Muaj cov pa oxygenation siab heev & electrophoresis ntau lawm kab, thiab tuaj yeem tsim cov pa oxygenation, electrophoresis, polishing, thiab lwm yam khoom lag luam.

Anodizing rau lub tsev profiles

Anodizing rau heatsink

Anodizing rau Industrial Aluminium Profiles-1

Anodizing rau Industrial Aluminium Profiles-2

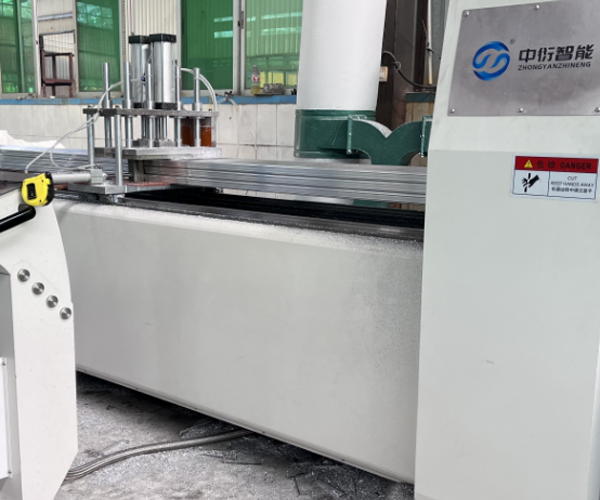

7. Pom Hlais Center

Cov cuab yeej sawing yog tag nrho tsis siv neeg thiab high-precision sawing khoom. Lub sawing ntev tuaj yeem hloov kho dawb, kev pub mis ceev ceev, sawing ruaj khov, thiab qhov tseeb yog siab. Nws tuaj yeem ua tau raws li cov neeg siv khoom xav tau ntawm qhov sib txawv ntawm qhov ntev thiab qhov ntau thiab tsawg.

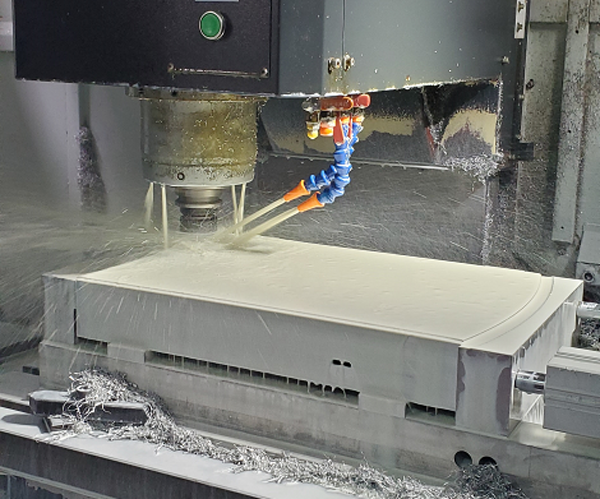

8. CNC sib sib zog nqus ua

Muaj 18 teeb ntawm CNC machining chaw cov cuab yeej, uas tuaj yeem ua haujlwm ntawm 1000 * 550 * 500mm (ntev * dav * qhov siab). Lub machining raug ntawm cov cuab yeej tuaj yeem ncav cuag 0.02mm, thiab cov khoom siv pneumatic fixtures hloov cov khoom sai sai thiab txhim kho lub sijhawm ua haujlwm ntawm cov khoom siv.

Cov khoom siv CNC

Cov khoom siv CNC

Cov khoom tiav

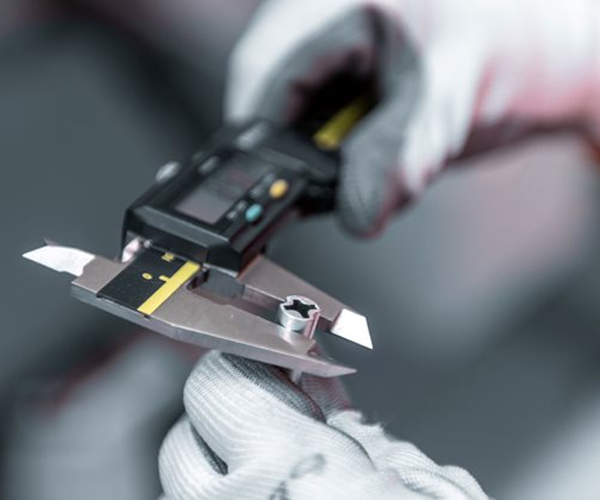

9. Kev tswj kom zoo - Kev kuaj lub cev

Peb tsis tau tsuas yog kev tshuaj xyuas phau ntawv los ntawm QC cov neeg ua haujlwm, tab sis kuj tseem muaj Kev Siv Hluav Taws Xob Optical Image Coordinate Measuring Tshuab ntsuas ntsuas ntsuas qhov ntsuas qhov sib txawv ntawm qhov loj ntawm cov heatsinks, thiab 3D kev ntsuas ntsuas ntsuas rau peb-dimensional soj ntsuam ntawm cov khoom txhua qhov ntev.

Kev ntsuas phau ntawv

Automatic Optical Image Coordinate Measuring Tshuab

3D ntsuas tshuab

10.Quality control-Chemical Composition Test

Tshuaj muaj pes tsawg leeg thiab concentration test-1

Tshuaj muaj pes tsawg leeg thiab concentration test-2

Spectrum analyzer

11. Kev tswj xyuas zoo-Kev sim thiab cov khoom siv kuaj

Tshuaj tsuag ntsev

Loj scanner

Tensile xeem

Qhov kub thiab txias tsis tu ncua

12. Ntim

13. Chaw thau khoom & xa khoom

Logistic Supply-Chain

Kev thauj mus los yooj yim network los ntawm hiav txwv, av thiab huab cua