Dab tsi yog qhov kev kho deg rau aluminium profile?

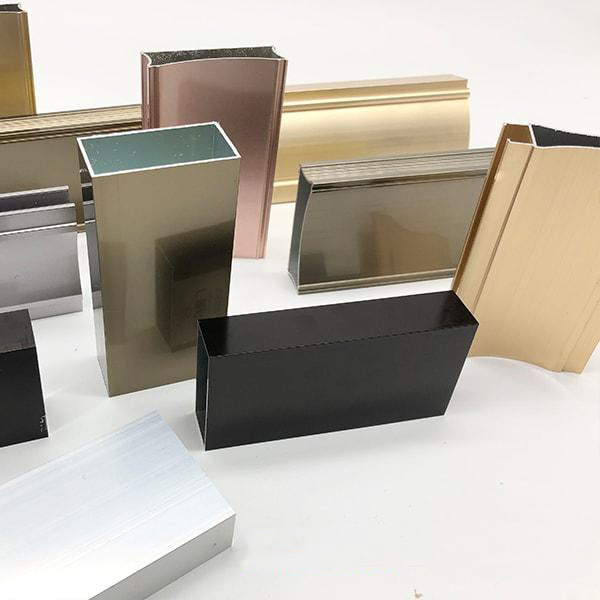

Kev kho saum npoo yog txheej txheej los yog txheej txheem uas siv cov txheej txheem los yog hauv cov khoom siv. Muaj ntau yam kev kho mob saum npoo av muaj rau txhuas, txhua tus nrog nws tus kheej lub hom phiaj thiab kev siv tswv yim, xws li kom zoo nkauj dua, zoo dua nplaum, lossis corrosion resistant, thiab lwm yam.

Nrog rau kev txhim kho txuas ntxiv ntawm tib neeg txoj kev ua neej nyob, qhov yuav tsum tau ua rau cov tsos thiab xim ntawm lub qhov rooj thiab qhov rais tau nce siab dua, thiab nrog kev ua kom zoo dua qub ntawm cov cuab yeej siv aluminium, qee qhov kev kho deg nyuaj tau vam meej. Cov txheej txheem kev kho aluminium nto peb feem ntau pom muaj xws li electrophoresis, anodizing, hmoov txheej, PVDF txheej, ntoo grain thiab lwm yam.

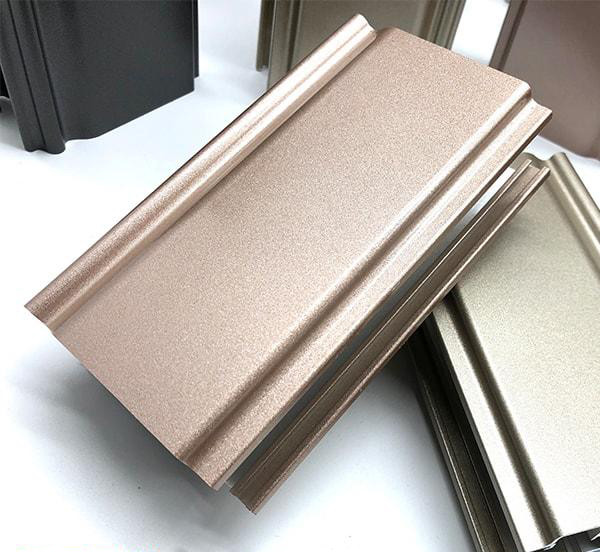

1. Electrophoresis

Electrophoresis yog txheej txheej electrophoretic ntawm cathode thiab anode. Nyob rau hauv qhov kev txiav txim ntawm qhov hluav taws xob, cov txheej txheem ions txav mus rau cathode thiab cuam tshuam nrog cov alkalinity tsim los ntawm cathode nto los tsim cov tshuaj insoluble, uas tau tso rau ntawm qhov chaw ua haujlwm. Aluminium profile electrophoresis yog hais txog cov txheej txheem ntawm kev tso cov extruded aluminium alloy nyob rau hauv lub tank electrophoresis, thiab tsim ib tug ntom resin zaj duab xis rau saum npoo tom qab dhau los ntawm cov tam sim no. Electrophoretic aluminium profiles yog qhov ci heev thiab muaj lub ntsej muag iav, uas kuj txhim kho corrosion kuj.

Txheej Txheem Flow:

Electrolysis (decomposition) ➤ Electrophoresis (migration, migration) ➤ Electrodeposition (precipitation) ➤ Electroosmosis (lub cev qhuav dej)

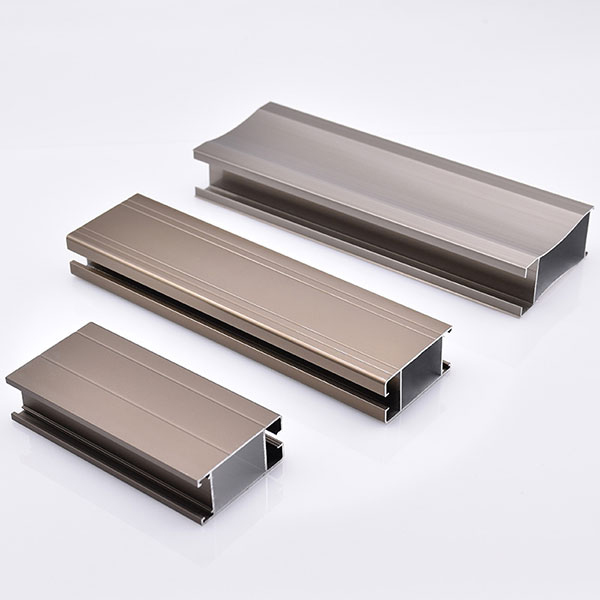

2. Anodizing

Anodized aluminium profiles xa mus rau cov txheej txheem uas txhuas thiab nws cov alloys tsim cov yeeb yaj kiab oxide ntawm cov khoom siv txhuas (anodes) nyob rau hauv cov khoom siv electrolyte thiab cov txheej txheem tshwj xeeb hauv kev ua haujlwm ntawm kev siv tam sim no. Txawm li cas los xij, oxide zaj duab xis tsim nyob rau saum npoo ntawm anodized aluminium yog txawv ntawm cov oxide zaj duab xis, thiab anodized txhuas tuaj yeem dyed los ntawm electrolytic xim. Txhawm rau kom kov yeej qhov tsis xws ntawm aluminium alloy nto hardness, hnav tsis kam, thiab lwm yam, nthuav dav ntawm daim ntawv thov, thiab ua kom lub neej ntev kev pab cuam, kev kho tshuab saum npoo tau dhau los ua qhov tseem ceeb ntawm kev siv aluminium alloys, thiab anodic oxidation technology yog tam sim no feem ntau siv thiab ua tiav. ntawm.

Txheej Txheem Flow:

Degreasing ➤ Chemical Polishing ➤ Acid Corrosion ➤ Stripping Black Film ➤ Anodizing ➤ Pre-Dyeing Treatment ➤ Dyeing ➤ Sealing ➤ Qhuav

Qhov sib txawv ntawm anodizing thiab electrophoresis: anodizing yog oxidized ua ntej thiab tom qab ntawd xim, thaum electrophoresis yog xim ncaj qha.

3. hmoov txheej

Siv cov khoom siv electrostatic hmoov txau los txau cov hmoov txheej rau ntawm qhov chaw ua haujlwm. Nyob rau hauv qhov kev txiav txim ntawm hluav taws xob zoo li qub, cov hmoov yuav sib npaug adsorbed rau ntawm qhov chaw ntawm lub workpiece los tsim cov hmoov txheej. Ntau yam txheej txheej kawg. Cov nyhuv txau yog qhov zoo tshaj rau cov txheej txheem txau ntawm cov khoom siv zog, adhesion, corrosion resistance, thiab aging kuj.

Txheej Txheem Flow:

Kev kho saum npoo av ➤ txau ➤ ci kho

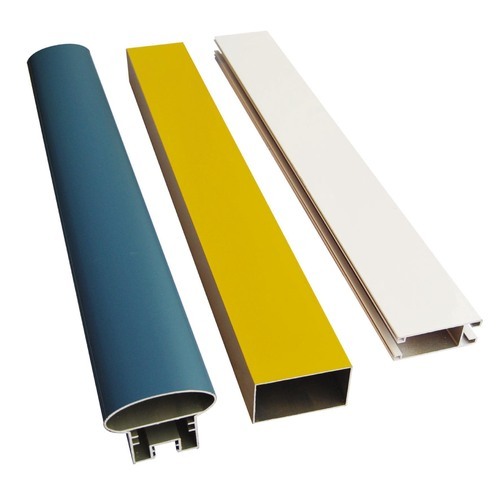

4. PVDF Txheej

PVDF Txheej yog ib hom tshuaj tsuag electrostatic, uas kuj yog ib txoj kev ua kua. Cov tshuaj fluorocarbon txau siv yog txheej txheej ua los ntawm ci polyvinylidene fluoride resin ua cov khoom siv hauv paus lossis nrog hlau txhuas hmoov ua cov xim. Muaj hom suspended thiab semi-suspended hom. Hom raug tshem tawm yog kev kho ua ntej thiab txau ntawm cov ntaub ntawv txhuas, thiab cov ntaub ntawv txhuas raug tshem tawm thaum lub sijhawm kho. Cov txheej txheem fluorocarbon zoo tshaj plaws muaj cov xim hlau nplaum, cov xim ci thiab pom tseeb ntawm peb sab.

Txheej Txheem Flow:

Kev kho ua ntej: degreasing thiab decontamination ntawm txhuas ➤ ntxuav ➤ alkali ntxuav (degreasing) ➤ ntxuav ➤ pickling ➤ ntxuav ➤ chromizing ➤ ntxuav ➤ ntxuav dej ntshiab

Txau cov txheej txheem: txau primer ➤ topcoat ➤ tiav xim ➤ ci (180-250 ℃) ➤ kev tshuaj xyuas zoo

Qhov sib txawv ntawm electrostatic hmoov txau thiab fluorocarbon txau: hmoov txau yog siv cov khoom siv tshuaj tsuag hmoov (electrostatic spraying tshuab) los txau hmoov txheej rau ntawm qhov chaw ua haujlwm. Nyob rau hauv qhov kev txiav txim ntawm hluav taws xob zoo li qub, cov hmoov yuav sib npaug adsorbed rau ntawm qhov chaw ntawm lub workpiece los tsim cov hmoov txheej txheej. Fluorocarbon spraying yog ib hom tshuaj electrostatic txau, uas kuj yog ib txoj kev ua kua. Nws yog hu ua fluorocarbon txau, thiab nws yog hu ua curium roj hauv Hong Kong.

5. Ntoo grain

Ntoo grain hloov profile yog raws li cov hmoov txau los yog electrophoretic painting, raws li lub hauv paus ntsiab lus ntawm high kub sublimation tshav kub nkag, los ntawm cua sov thiab siab, cov ntoo grain qauv ntawm daim ntawv hloov lwm lub tsev los yog hloov zaj duab xis yog sai sai thiab nkag mus rau cov profiles uas tau txau los yog electrophoresis. Cov ntoo-grain profile uas tsim muaj kev ntxhib los mos, muaj zog peb-dimensional nyhuv, thiab tuaj yeem cuam tshuam qhov zoo ntawm cov ntoo grain. Nws yog ib qho zoo tagnrho lub zog-txuag thiab ib puag ncig tus phooj ywg cov ntaub ntawv los hloov cov tsoos ntoo.

Txheej txheem Flow:

Xaiv cov substrate ➤ qhwv cov ntawv luam ntawv ntoo ➤ Npog lub hnab yas ➤ Nqus ➤ Ci ➤ Tear tawm daim ntawv luam ➤ Ntxuav saum npoo

Rui Qifeng tuaj yeem cuam tshuam nrog ntau yam kev kho deg nyuaj rau cov ntaub ntawv architecture. Superior zoo thiab tus nqi tsim nyog, txais tos rau kev nug ntxiv.

Guangxi Rui QiFeng Tshiab Khoom Co., Ltd.

Chaw nyob: Pingguo Industrial Zone, Baise City, Guangxi, Suav

https://www.aluminium-artist.com/

Email:Jenny.xiao@aluminum-artist.com

Post lub sij hawm: Feb-20-2023