Aluminium extrusion yog ib qho kev ua tau zoo thiab ntau yam kev tsim khoom siv los tsim cov khoom siv nrog cov ntu ntu ntu. Nyob rau hauv lub plawv ntawm cov txheej txheem no yog ib qho ntawm cov tseem ceeb tshaj plaws ntsiab:lub extrusion tuag. Qhov no precision-engineered cuab tam zoo li txhuas nyob rau hauv lub siab loj thiab plays lub luag hauj lwm tseem ceeb hauv kev txiav txim siab cov khoom zoo, nto tiav, thiab qhov tseeb.

Dab tsi yog Aluminium Extrusion Tuag?

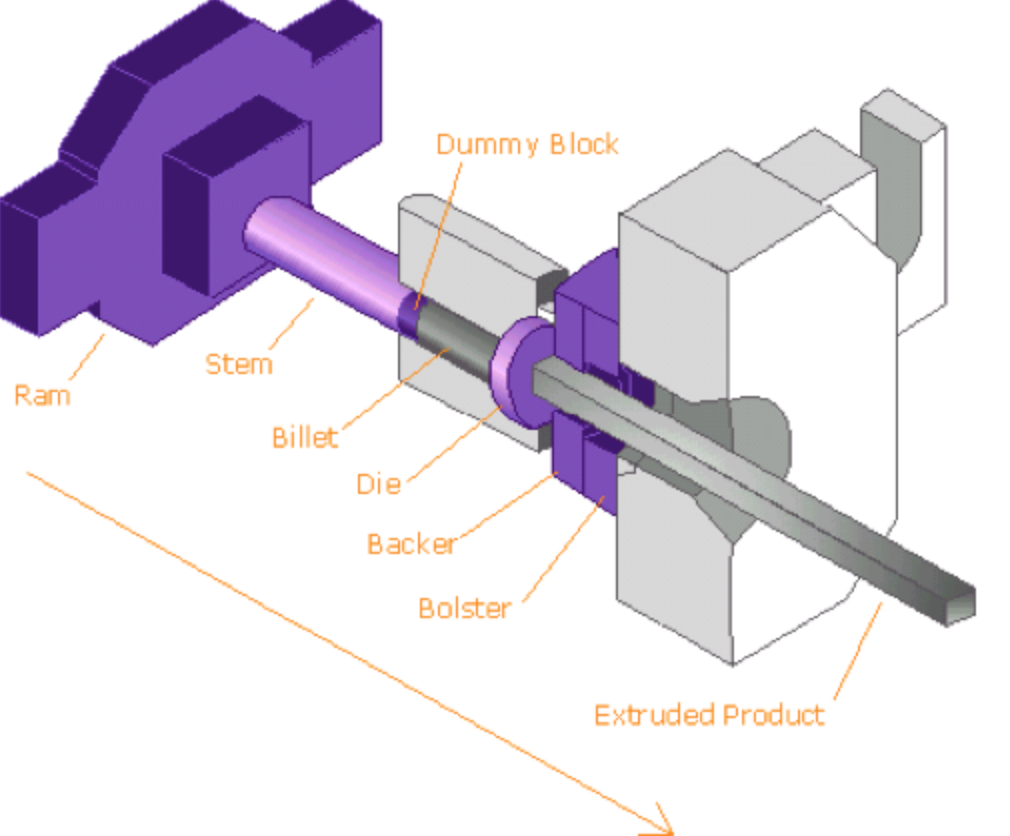

Ib qho extrusion tuag yog ib qho tshwj xeeb tsim cov cuab yeej steel nrog ib qho tshwj xeebtuag qhibuas ua rau cov aluminium zoo li nws raug yuam los ntawm kev kub siab. Nrog rau kev txhawb nqa cov cuab yeej xws li backers, bolsters, thiab sub-bolsters, cov tuag ua kom muaj kev sib raug zoo thiab kev ncaj ncees thaum lub sij hawm extrusion.

Hom Extrusion Tuag

Extrusion tuag yog categorized rau hauv peb hom loj raws li qhov xav tau profile geometry:

1. Khoom Tuag

Siv los tsim cov profile yam tsis muaj kab noj hniav - xws li tuav, cov ces kaum, lossis cov kab.

● Cov ntsiab lus:

○ Die Phaj: Muaj qhov zoo li tus orifice rau qhov kawg profile.

○Backer Phaj: Muab kev txhawb nqa tom qab tuag.

○Feeder Phaj (yeem): Pab hauv kev taw qhia cov khoom ntws.

2. Hollow Tuag

Tsim los rau cov profiles nrog cov voids sab hauv xws li cov raj lossis cov qhov rais thav duab.

●Cheebtsam:

○Mandrel (los yog core): Tsim cov kab noj hniav sab hauv.

○Tuag Cap: Tsim cov duab sab nrauv thiab tuav lub mandrel nyob rau hauv qhov chaw.

○Backer: Muab cov qauv kev txhawb nqa thiab kev tswj kom sov.

3. Semi-Hollow Tuag

Siv rau cov profiles nrog ib feem ntawm cov voids - sib txuas cov yam ntxwv ntawm cov khoom thiab hollow seem. Cov no yog cov zoo tagnrho rau complex geometries nrog txawv txawv phab ntsa thicknesses.

Cov txheej txheem Extrusion thiab Tuag Txoj Haujlwm

Cov kauj ruam tseem ceeb extrusion muaj xws li:

1.Billet Preheating:

Aluminium billets yog preheated rau 370-500 ° C (700-930 ° F) los txhim kho plasticity.

2.Loading & Extrusion:

Lub billet yog loaded rau hauv lub thawv, thiab ib tug hydraulic ram (nrog siab los ntawm 1,000 mus rau 15,000 tons) thawb nws los ntawm cov tuag.

3.Profile Tsim:

Lub txhuas siv cov duab ntawm qhov qhib qhov tuag thaum nws tawm, tsim cov profile uas yuav tsum tau ua.

4.Txias, Txiav & Tiav:

Profiles yog txias, ncab, txiav mus rau ntev, thiab tej zaum yuav undergo nto finishing zoo li anodizing los yog hmoov txheej.

Hauv qhov txheej txheem no,qhov tuag ua kom cov duab precision, nto zoo, thiab sib xws.

Die-Related Tolerances thiab Phab Ntsa Thickness Control

Precision yog qhov tseem ceeb. Aluminium extrusion tolerances nyob ntawm:

●Profile loj & complexity

●Phab ntsa thickness(cov phab ntsa nyias nyias ua kom nyuaj)

●Tuag hnav dhau lub sijhawm

●Phab ntsa thicknesstuaj yeem sib txawv me ntsis, tshwj xeeb tshaj yog rau cov tuag tshiab - thawj zaug extrusion tej zaum yuav thinner me ntsis, tab sis nrog kev siv, tuag stabilize thiab zoo dua ua raws li tus qauv nominal. Qhov no yog vim li casbatch tom ntejfeem ntau qhia me ntsis thicker thiab zoo sib xws.

Kev kam rau ua tau raws li cov qauv thoob ntiaj teb xws liTS EN 755-9los yogAA (Aluminium Association)specifications.

Tuag Nto kho thiab tu

Txhawm rau txhim kho kev ua haujlwm thiab kev ua neej, extrusion tuag feem ntau undergo:

Nitriding

Cov txheej txheem deg hardening uas diffuses nitrogen rau hauv qhov chaw tuag, ua kom tawv tawv thiab hnav tsis kam - qhov tseem ceeb rau kev tuav lub siab thiab kub.

Tuag Preheating (Tuag Cooking)

Kuj tseem hu ua "煲模(pab mo)"hauv Suav, qhov kev coj ua no maj mam ua kom cov tuag ua ntej extrusion kom txo tau cov thermal poob siab thiab txhim kho cov hlau ntws sib xws.

Common Die Challenges thiab Kev Tiv Thaiv Kev Ua Haujlwm

✅ Hnav thiab kua muag

Kev kub siab thiab kub ua rau maj mam hnav.Kev tshuaj xyuas tsis tu ncua, rov polishing, thiab rov ua nitridingncua lub neej tuag.

✅Ntog Defects

Kev khawb, kab tuag, lossis kev tsim kho tuaj yeem cuam tshuam rau qhov zoo. niaj hnubtuag tuthiabkev kho saum npoopab txo qhov tsis xws luag.

✅ Thermal Management

Cov cua kub tsis sib xws lossis cua txias ua rau muaj qhov tsis xws luag lossis tuag tawg. Kev rwb thaiv tsev kom zoo thiab tswj tau preheating yog qhov tseem ceeb.

✅ Kev sib tw thiab kev txhawb nqa

Kev sib raug zoo tsis zoo ua rau muaj qhov ua yuam kev me me thiab kev tuag ntxov ntxov. Lub caij nyoogrov calibrationthiabkev saib xyuasyog qhov tseem ceeb rau precision.

Vim li cas Tuag Matter hauv Aluminium Extrusion

Ib tug zoo-tsim, zoo-tso extrusion tuag ncaj qha cuam tshuam:

●Dimensional raug

●Profile complexity

●Extrusion ceev

●Nto tiav

●Zuag qhia tag nrho cov nqi khoom thiab sib xws

Xaiv txoj kev tuag zoo, nkag siab txog kev tswj cov phab ntsa tuab, thiab ua kom muaj kev tiv thaiv kev tiv thaiv zoo yog qhov tseem ceeb kom ua tiav cov txiaj ntsig zoo ib yam.

Nrhiav rau Kev Txhim Kho Kev Cai Tuag & Extrusion Tus khub?

Ntawm [Koj Lub Tuam Txhab Lub Npe], peb tshwj xeeb hauv precision aluminium extrusion thiab muab kev txhawb nqa tag nrho raukev cai tuag txoj kev loj hlob, qhov profile optimization, thiabtuag lub neej kev tswj xyuas. Txawm hais tias koj tab tom tsim khoom, hollow, lossis complex hybrid profiles, peb pab pawg neeg tsim khoom tau npaj los pab nrog cov kws tshaj lij kev pom thiab kev tsim khoom lag luam.

Tiv tauj peb hnub nokom paub ntau ntxiv txog yuav ua li cas peb tuaj yeem nqa koj cov qauv tsim rau lub neej nrog cov kev daws teeb meem zoo.

Email: yuav.liu@aluminium-artist.com

Lub vev xaib: www.aluminium-artist.com

Chaw nyob:Pingguo Industrial Zone, Baise City, Guangxi, Suav

Post lub sij hawm: Jun-17-2025